The art of making carpets was probably developed on the plains of Central Asia several thousand years ago. The nomad tribes needed some protection from the cold winters and something more easily handled, transportable and functional than the sheepskin coverings. At the same time they were also making decorations for their tents.

The materials used for the construction of the warp, weft and pile of the carpet came from the herds of goats and flock of sheep so readily available to them.

The looms, in their simplest form, were made of two wooden ribs which were secured to the ground and between them the warp was fastened. These horizontal looms, which are still used today by the nomads, have the advantage that they fold easily and can be moved to the next camp ground.

The patterns on these early carpets were composed of geometrical or curvilinear motifs.

The handmade carpets are made of transient materials and very old discoveries are rare. The oldest known carpet was found in the year of 1947 at excavations in Siberia. Named after its place of discovery the carpet is named the Pazyryk-carpet or the Gorny-Altai carpet. It measures 183 x 200 cm and framed by a border of griffins. It has a knot density of approximately 360,000 knots per square meter. The craftmanship of Its construction is of the highest quality and the carpet has a higher knot density than most carpets seen in stores today. The pattern is very interesting, the middle consists of a ribbon motif, in the border you can see a procession with deer and in another border with warriors on horses. This carpet was probably manufactured in Armenia or Persia around 400 B.C. and when it was discovered it had been deeply frozen in a block of ice, which is why it is so well-preserved. The carpet can be seen at the "The State Hermitage Museum, St. Petersburg, Russia".

The Pazyryk Carpet, the oldest surviving carpet in the world.

The Pazyryk Carpet, the oldest surviving carpet in the world.

In the 16th century, during the protection of the emperors, the art of carpets was developed in Persia and in India both technically and artistically, for example in court workshops. During this period probably the most splendid and perhaps the most famous rug in the world, the Ardabil carpet was produced. Originally there were two carpets but one was sacrificed in order to repair the other. The carpets are considered some of the best of the classical Iranian (Persian) school of carpet creation. They were first placed in a mosque in Ardabil and they measure 534x1152 cm and were probably manufactured in the city of Kashan in Persia by Maqsud. The carpets date back to the year 946 after an Islam count, which is 1539 A.D. and it took three years for five weavers to complete the carpet, which was ordered by Shah Tahmasp for the Sheikh Safi mosque.

The Ardabil-carpet.

The Ardabil-carpet.

The best-preserved carpet can be seen at Victoria and Albert Museum in London. The remaining parts of the sacrificed rug can be viewed at the Los Angeles County Museum, USA. The carpet is made by persian knots, pile of wool, warp and weft by silk; with a knot density of 518.000 knots per square meter. The carpet was sold in the 19th century in order to pay for repairs of the great mosque in Ardabil, north of Persia.

At "The Museum of National Antiquities in Sweden" you can see the "Marby Carpet". This carpet is made in Turkey in the beginning of the 15th century and was brought to Stockholm via a small village named Marby. Perhaps the most premier treasure at Stockholm Castle is the persian hunting rug from late 16th century. This carpet was probably brought to Sweden from the sovereign house of Holstein-Gottorp as part of the future queen Hedvig Eleonoras brides dress before her marriage with Karl X Gustav.

The Marby carpet.

The Marby carpet.

Around 1000 A.D., Marco Polo brought back news of rug making from his journeys through central Anatolia (modern Turkey). With trade and the Crusades, the importation of carpet and the techniques employed in their making soon found their way into France and England in the early 1500’s. In France, the purchase of rugs from the Middle East became so heavy that the flow of wealth out of France affected the economy…so much so that in 1608, Henry IV took it upon himself to start a carpet factory in his palace at the Louvre to create rugs for the French market in order to keep the wealth within France. Unfortunately for his plan, the resulting rugs made in the Oriental method but with French motifs so pleased him that he reserved them for royal use and they never made it to his subjects. His successor Louis XIII started an outside workshop to create these “French Orientals” which came to be known as “Savonneries” (after the old soap factory they were produced in) and were Europe’s first original carpet designs. These French designs had some success, but the Middle Eastern rugs were still the preferred choice.

England soon followed suit with the first carpet factory being built in Wilton in 1655. With the advent of the Industrial Revolution, carpet manufacturing soon shifted gears from a strictly cottage industry to a commercial one. Other methods of carpet weaving soon developed using readily available natural fibers. With increasing demand and technological development, synthetic materials, as well as dyeing methods, evolved to meet the increasing demand for more and different materials, colours and patterns, leading to the variety of carpets we now have today.

Axminster carpet was a unique floor covering made originally in a factory founded at Axminster, Devon, England, in 1755 by the cloth weaver Thomas Whitty. Resembling somewhat the Savonnerie carpets produced in France, Axminster carpets were symmetrically knotted by hand in wool on woolen warps and had a weft of flax or hemp. Like the French carpets, they often featured Renaissance architectural or floral patterns; others mimicked oriental patterns. Similar carpets were produced at the same time in Exeter and in the Moorfields section of London and, shortly before, at Fulham in Middlesex. The Whitty factory closed in 1835 with the advent of machine-made carpeting. The name Axminster, however, survived as a generic term for machine-made carpets whose pile is produced by techniques similar to those used in making velvet or chenille.

Axminster carpet, late 18th or early 19th century.

Axminster carpet, late 18th or early 19th century.

The carpet industry in the United States began in 1791 when William Sprague started the first woven carpet mill in Philadelphia. Others opened during the early 1800s in New England. Included in that area was Beattie Manufacturing Company in Little Falls, New Jersey, a company that operated until 1979.

In 1839, Erastus Bigelow permanently reshaped the industry with the invention of the power loom for weaving carpets. Bigelow’s loom, which doubled carpet production the first year after its creation and tripled it by 1850, is now part of the Smithsonian Institution’s collections. He continued to devote his life to innovation — 35 separate patents were issued to him between 1839 and 1876. Bigelow introduced the first broadloom carpet in 1877.

The power loom with Jacquard mechanism was developed in 1849, and Brussels carpet was first manufactured by the Clinton Company of Massachusetts. The Brussels loom was slightly modified, making possible the manufacture of Wilton carpet. Later, the Hartford Carpet Company joined with Clinton Company to become Bigelow Carpet Company.

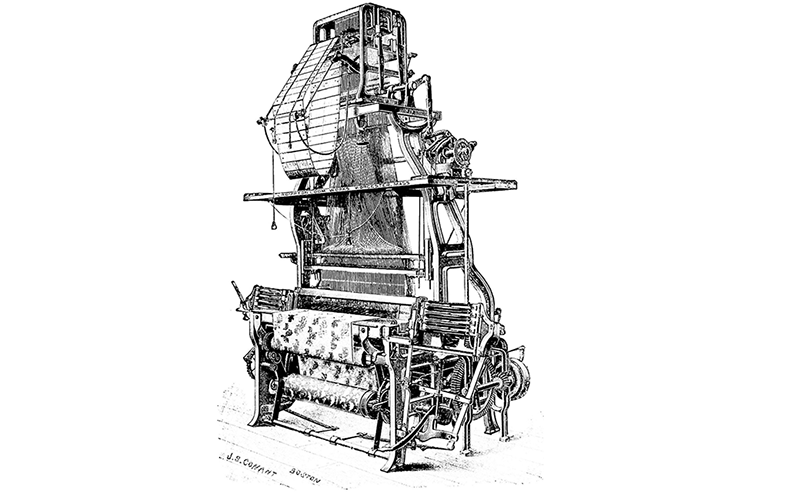

Bigelow Power Loom - 1839

Bigelow Power Loom - 1839

With the coming of the Industrial Revolution — and the invention of the department store in the middle of the 19th century, this began to shape the purchasing desires of the burgeoning middle-classes — things began to move quickly within the carpet industry, with innovation following innovation, most notably the Gripper Axminster loom that increased the speed of production hugely, which inevitably reduced prices and increased volume sales that were already becoming linked to a housing boom in England that, by the 1880s, was increasing two-fold every year.

Hand woven Chenille Axminster Loom 1890's

Hand woven Chenille Axminster Loom 1890's

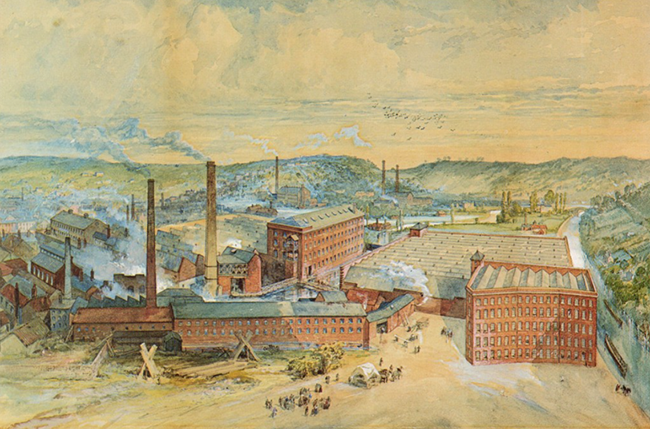

Kidderminster was a small Worcestershire town in the 18th and 19th centuries. It produced woolen cloth in the 17th century and developed as a location for carpet manufacturing in the 18th century. By the mid-19th century, Kidderminster developed into a factory town and one of the most important centers for carpet making in Britain. In 1890 Brintons develop the 'Gripper' Axminster Loom.

Brintons Carpet Factory - Kidderminster, England. 1870

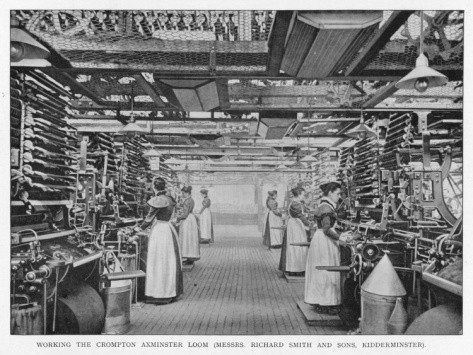

The new automatic Gripper Axminster Looms in action in Kidderminster 1890's

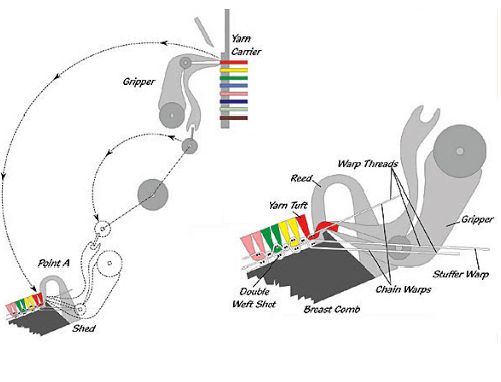

Gripper Axminster Weaving

In the 1940s a group of American textile technicians took part of the Gripper Axminster method of weaving, and part of the Wilton method of weaving, and created a wholly non-woven method of creating a carpet called ‘tufting’. All tufting means is that the same creels with the same bobbins feed the face of a tufting machine instead of a loom, with each individual thread loaded into a line of large fixed needles placed at the face of a pre-woven fabric that is destined to become the backing of the carpet. Each needle then passes through and back out of the pre-woven backing at speed as it moves forward, creating — as with the Wilton — a loop which is then cut by a blade at the end of the needle. At full throttle a tufting machine can produce upward of ten kilometers a day. This invention, coupled with that of Nylon and Acrylic yarns, changed the carpet industry forever.

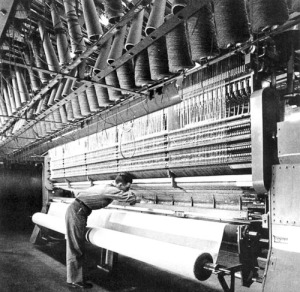

Tufted Carpet Loom - Dalton, Georgia, USA - 1940's

Tufted Carpet Loom - Dalton, Georgia, USA - 1940's

The evolution of carpeting has been affected by social, economical and fashion pressures. Developments in man-made fibers, loom widths and machine efficiencies brought carpets within reach of the mass market. Fashions for seamless square and then seamless close-cover carpet helped introduce wider looms. Investigation into thermal and acoustical requirements led to fitted carpets in public buildings, shops and offices. Ingenious manufacturing solutions proliferated from the 1960's. Tiles, printing, warp printing, needle punched fibers and double-faced bonded carpets all increased the ability of the carpet trade to cater for specific areas, price points and the demands of fashion.